Instructions

- Enter screw diameter, pitch and tensile strength. Stress area and ultimate tensile load will be auto generated.

- Tensile strength can be chosen from the preset buttons, or by manually setting a value of choice.

- The calculation will begin automatically soon as the input data is set.

About the calculation

Ultimate tensile load = Stress area*Tensile strength

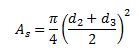

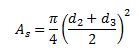

The tensile strength is given by the fasteners property class. The stress area is calculated with the formula stated in ISO 8908-1:

Where d2 is the basic pitch diameter of the thread and d3 is the minor diameter of the thread.

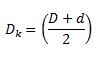

In which d1 is the basic minor diameter and H is the height of the fundamental triangle of the thread.

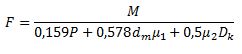

Torqued tensile load = Ultimate Tensile Load * Torsional Stress Factor

The torsional stress gained from applying tightening torque to the bolt reduces the maximum tensile force the bolt can achieve before fracture. The Torsional Stress Factor is proportional to the thread friction, µth. E.g. if the thread friction is µth0,14, the Torsional Stress Factor is 0,86 (1-0,14).

Because of the difficulty in finding reliable thread friction figures, in this app we use Torsional Stress Constant equal to 0,8. I.e. µth0,2.

Finnveden Bulten - BuProx

Finnveden Bulten - BuProx